Dr T.B Barragry PhD, MSc, MVB, MRCVS, Dip ECVPT. Veterinary pharmacologist.

The aim in making good silage and indeed in storing any crop, is to keep its nutritional quality as close as possible to that of the original harvested crop and to avoid losses during silage making. This means minimizing losses of dry matter and nutrients and ensuring proper fermentation and preservation. The ultimate success of this process depends on several factors, such as decisions made when cutting, harvesting, and ensiling the crop.

The Fermentation Process

Silage making is a chemical process and achievement of proper chemical fermentation is the key factor in the preservation of silage, which ultimately converts fresh harvested grass into grass silage.

Successful silage making is based on the simple science of good and proper fermentation by desirable anaerobic (no oxygen) microorganisms, and the exclusion and prevention of the growth and establishment of deleterious oxygen dependant microorganisms (aerobic).

High sugar content and high dry matter levels in the original herbage, favour the process of rapid fermentation and thus the development of good quality silage. Grasses can begin to lose glucose and carbohydrates soon after they are cut, and these sugars are the important substrates for the good fermentative bacteria. The key to high-quality grass silage is to dry the crop to an appropriate dry matter (DM) level for ensiling as quickly as possible.

A critical feature in ensuring good silage is bacterial fermentation, a rapid drop in pH and the production of lactic acid. During the process of fermentation, glucose and other sugars sugar are converted into acid, predominantly lactic acid, by specialized bacteria, and this low pH acts as a preservative.

Silage Inoculants

For good silage, the key factors are firstly to ensure the exclusion of oxygen, thereby creating an anaerobic environment (oxygen free) in which anaerobic Lactic acid bacteria can grow and multiply. This will result in speedy acid production, with an ensuing low ph to preserve the nutritive quality of the silage and inhibit the growth of spoiler aerobic micro-organisms. Lactic Acid bacteria (LAB) are crucial for inducing this rapid acidity, effecting good fermentation and optimal quality silage. Some acetic acid production is also desirable. Acetic acid produced by Heterofermentativebacteria such as Lactobacillus buchneri and Propionibacterium acidipropionici is an effective yeast and mould inhibitor.

The proper use of a research-proven, acid producing forage inoculant is crucial to creating high-quality silage, and Homofermentative lactic acid bacteria are highly effective here. Homofermentativelactic acid bacteria (LAB) are bacteria which convert soluble sugars from the forage into lactic acid. These bacteria are used to speed up the initial fermentation, helping to quickly reach a low ph. Examples include Lactobacillus plantarum, Pediococcus acidilactici, Enterococcus faecium and Lactobacillus salivarius.

A number of commercial silage inoculants currently on the market are presentations containing either one, two or three strains of Lactobacilli and other acid producing organisms. Many of these inoculants also contain added enzymes, anti-oxidants, and prebiotics. Advance+ Silage Inoculant from Provita Animal Health is a potent triple strain inoculant given at very high inclusion rates into the silage, providing a wide range of acidifying and other potentiating benefits.

Research Trials with Advance+

Silage making is a chemical process and must be regarded as such. The use of evidence based scientifically proven inoculants containing triple strains of lactic acid bacteria is a good investment and highly cost effective. Science works!

Summary of 11 fermentation Trials with Advance+ submitted to EU

Performance Benefits – Dairy, Store Beef and Finishing Beef

Advance+ Silage Inoculant contains three unique Lactic acid producing bacterial strains of with added enzymes and sugars as prebiotics. The major striking characteristic of these bacteriais not only their ability to produce lactic and acetic acid, but in addition are known to secrete antimicrobial substances called bacteriocins. Many enterococci produce at least one bacteriocin, which is a ribosomally synthesized antimicrobial peptide, active against a wide range of gram positive spoiler organisms and foodborne pathogens including Listeria. Evidence suggests that bacteriocins or bacteriocin-like substances (BLISs) produced by P.pentosaceous play effective antibacterial roles in the microbial ecosystem, inhibiting undesirable spoilage organisms (e.g., Clostridia, Bacillus, fungi) and also in preventing heating of the silage.Use of this unique triple strain inoculant will result in a drier, sweeter smelling silage with high sugar and high dry matter content.

Advance+ Performance:

✔ Rapidly lower the silage pHProduce lactic acid and acetic acids

✔ Produce bacteriocins

✔ Kill other contaminating organisms

✔ Ensure excellent silage quality

✔ Contains proven organisms in silage trials

✔ EU approved and accepted

Evidence Based Efficacy of Advance +

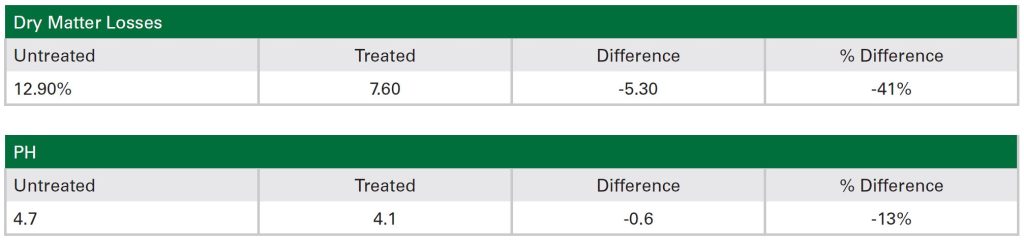

Advance+ is a mixture of lactic and acetic acid bacterial strains at a high guaranteed rate of inclusion of 1.2 million organisms per gram of forage. The product has been subjected to EU authorisation and approved and has been subjected to numerous detailed nutrient quality trials in research institutes. Results in these trials have recorded the occurrence of a more rapid fermentation rate, quicker and lower acidic pH, better preservation, higher sugar, protein, and dry matter content, and to be highly cost effective.

Provita Advance+ provides such dependable results because of the unique EU-approved triple strain combination. All strains of bacteria in Advance+ are registered with the European Food Safety Authority (EFSA) which requires extensive dossiers covering quality, safety, and proof of efficacy. Advance+ is also proven in numerous field trials and with Research institutes such as AFBI. Being a multi-strain product increases the reliability over a wider range of conditions also which is very useful for the unpredictable weather conditions and herbage types and quality. Applied at the recommended rate, Advance+ is guaranteed to supply 1.2 million bacteria per gram of forage. This high level of inoculant means sufficient numbers of bacteria are present to kick start and accelerate the fermentation process and to guarantee low moisture, high sugar, high protein, and higher, DM levels.