The good news for the dairy farming industry is that the Agricultural Price Index indicates that input cost inflation has eased. However, input costs remain historically high and with falling milk prices profit margins are being squeezed. The continuing uncertainty about changes to agricultural subsidy schemes is leading producers to review their future, and the number leaving the industry is greater than in previous years.

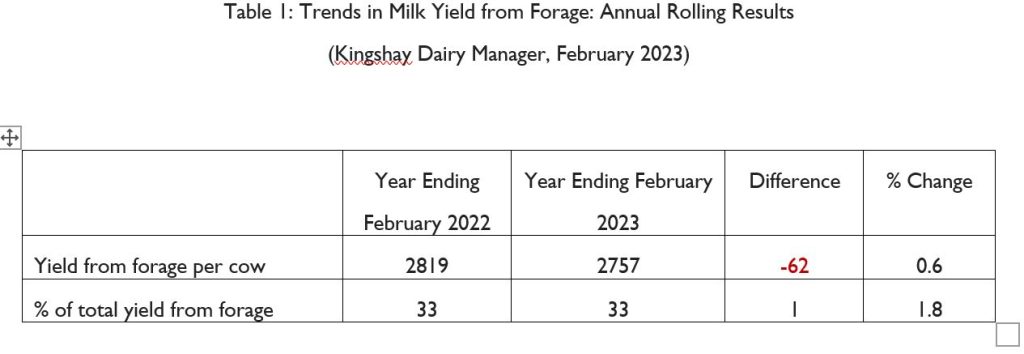

Now more than ever those continuing in milk production must focus on feed efficiency and improving milk produced from forage – in Northern Ireland it has been reported that the price of a kilo of concentrate on most dairy farms is above the price received for a litre of milk (DAERA, 27 April 2023). It has also been shown by Kingshay (23 April 2023) that the rolling trend in milk from forage for the year ending February 2023 was down 62 litres to 2757 litres per cow and remains static at 33% of total yield from forage. Re-focussing on forage quality is one step that can be taken to improve this.

Ensiling – how it works.

Ensiling is the most common method of forage preservation in Europe and the US and is increasing in popularity in Asia-Pacific. The process allows the provision of valuable nutrition during the colder, wetter months when grazing is impossible or restricted, and in areas where a damp climate severely limits the ability to make and store hay.

Silage-making relies on the process of fermentation as do foods such yoghurt, kefir, sauerkraut and kimchi that becoming increasingly popular and recognised for their health benefits.

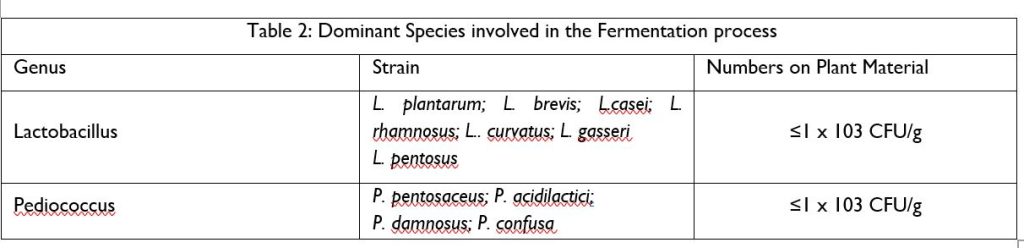

When silage is made epiphytic Lactic Acid Bacteria (LAB) present on the forage metabolise sugars into lactic acid reducing the pH and preventing the growth of undesirable micro-organisms.

However, the numbers and types of bacteria present on the ensiled material are unable to create the conditions required to preserve the material efficiently, and for the length of time required by livestock products – up to one year is desirable. There is a wide variation in the numbers of key epiphytic LAB present on plant material (as low as 10 cfu/g on alfalfa up to 1 x 107 cfu/g on sorghum, and maize) as shown in Table 2 below, and these low numbers can be lower in periods of cool weather.

The production of good quality, stable silage can therefore require stimulation and for about 40 years inoculants, based on carefully selected strains of LAB, have been used to kick-start fermentation. Inoculants are particularly beneficial when ensiling green forages with a low content of fermentable sugars, and/or a high protein content or buffering capacity that neutralises acid.

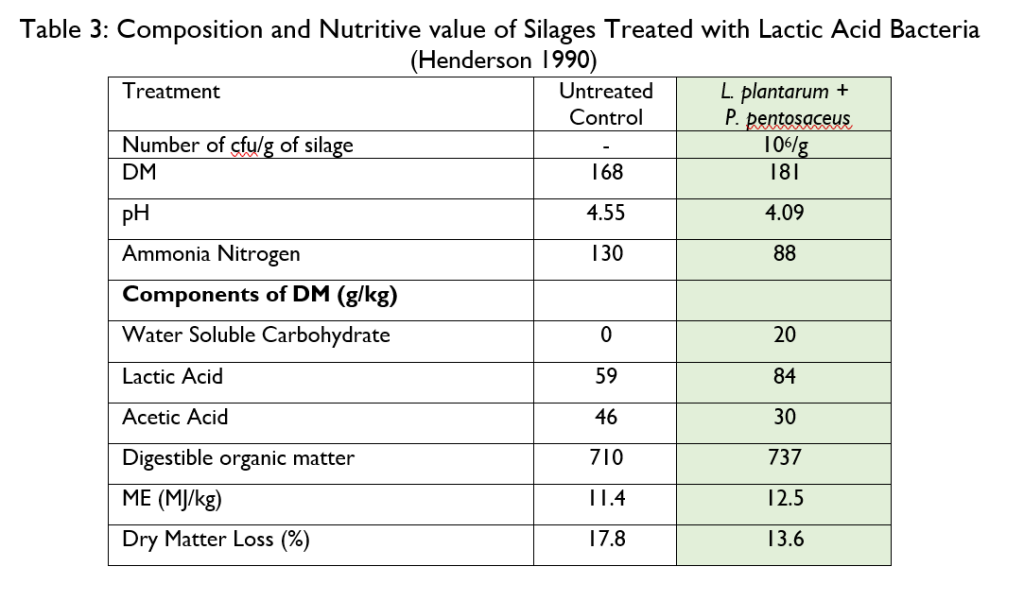

Early research conducted in Edinburgh and published in 1990 illustrated the benefits of inoculating silage with single or multiple strains of LAB on the nutrient analysis of grass silage:

The addition of the inoculant indicates more efficient fermentation of the silage – increased lactic acid and reduced pH, resulting in lower dry matter losses and a better yield.

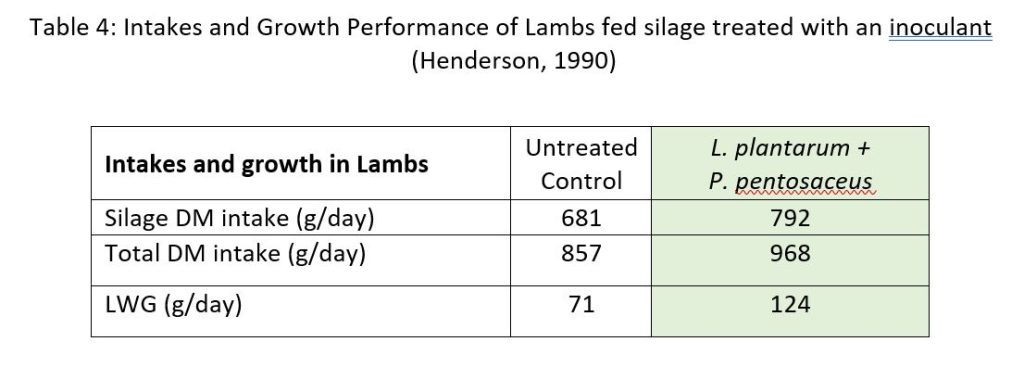

The energy content and digestible organic matter were also found to be higher with the use of the inoculant which was reflected in the performance of lambs fed the inoculant treated silage.

The explanation for this was considered to require further experimentation and 30 years later microbiological research has gone a long way in explaining these animal performance benefits.

Inoculants: Extraordinary Benefits

The most up-to-date inoculant formulations combine strains that produce a stable well-preserved silage, that remains stable when the clamp is opened and feed-out. In addition, strains have now been identified which give what might be described as extraordinary benefits including:

- Alteration of the cell wall structure to improve the rate and extent of hemicellulose digestion.

- Prevention of growth of filamentous fungi

- Detoxification of mycotoxins

- Environmental impact

- Limiting the development of pathogens

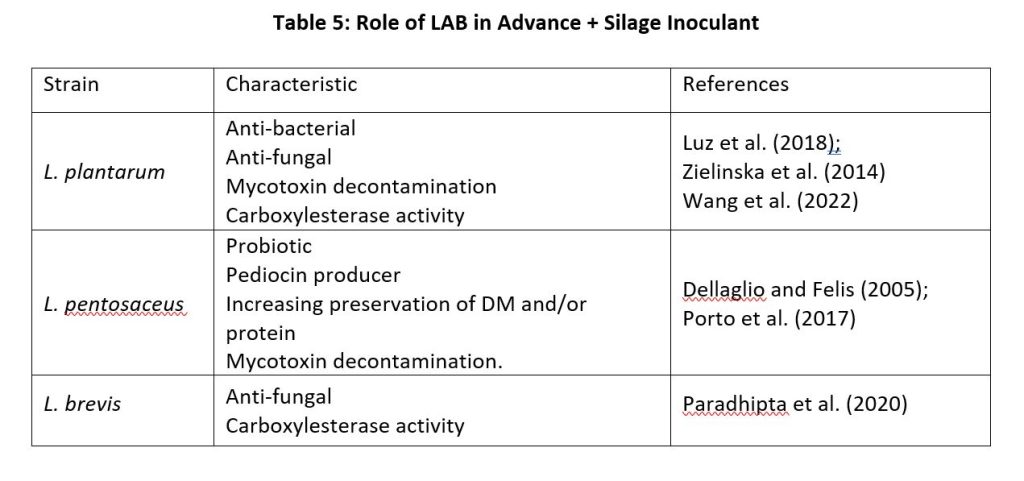

One such inoculant is Advance+ that has been formulated following many years of research, using a combination of mini-silo, split clamp and on-farm trials. This superior formulation can be used on grass, wholecrop cereal and maize silages. The formulation contains the strains shown below which have been shown to benefit the silage making process in several ways:

LAB: Alteration of the cell wall structure

Plant cell walls are the main source of energy in the rumen, but their complex structure can mean that <50% of the cell wall is utilised by ruminant livestock.

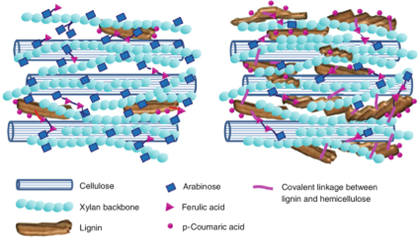

Research has illustrated that the levels of lignin and phenolic acids in cell walls can be an impediment to digestion. The most abundant phenolic acids, Ferulic and p-Coumaric acid link to arabinoxylans and lignin and Grabber (2005) described these bonds as “spot welding on a stell mesh frame” that play a key role in the inhibition of forage degradation.

There is increasing evidence that LAB used to preserve silage and reduce process losses, may also be responsible for the release of ferulic acid from plant cell walls increasing its fermentability, and hence the nutritional value of the silage. Based on changes in fermentation characteristics during the first 60 days of ensiling of whole maize crops Wang et al. (2022) concluded that the addition of a mixed inoculant containing 60% L. plantarum , 10% P. pentosaceus and 30% L.. buchneri improved silage quality through a rapid fall in pH and greater lactate production when compared to a single strain.

The mixed inoculant also facilitated the release of the ferulic and p-coumaric acids which is thought to be due to the production of enzymes by the bacteria.

In vitro studies rumen fermentation studies conducted by the same team confirmed that the mixed inoculant facilitated the microbial digestion of lignified fibre in maize silage.

LAB – Environmental Benefits

Wang et al., 2022 were also able to demonstrate that the use of a mixed inoculant (60% L. plantarum , 10% P. pentosaceus and 30% L.. buchneri) shifted the rumen fermentation towards greater propionate production, and lower methane production a most valuable benefit as ruminant livestock producers seek to reduce emissions of greenhouse gases that can impact the climate.

Mycotoxin Decontamination

Mycotoxins are known to be a problem in maize silages in EU: in 2019 87% of maize silages contained at least 5 mycotoxins, 67.7% containing the regulated mycotoxins DON and Zearalenone which have implications for gut health and reproductive performance (Reisinger et al., 2019). The results of a more recent survey conducted in Belgium and published in 2021 showed that all of the 158 samples of maize silage contained at least two different mycotoxins with DON, NIV and the emerging mycotoxin Enniatins B the most commonly occurring toxins at levels which exceeded EU recommendations (Vandicke et al, 2021).

The results of the Belgian study were based on initial contamination before ensiling, which were found to reduce during the ensiling process. Could this be an extraordinary benefit of LAB in maize silage?

It is known that LAB produce many compounds with antibacterial activity that can inhibit the growth of Molinia, Aspergillus, Penicillium and Fusarium fungi which all have the potential to produce mycotoxins that can have a negative effect on animal performance. The fungistatic effect of LAB is thought to be due to the production of peptides based on proline and phenylalanine, glycine and leucine which occurs at concentrations of mg/cm3 – theanti-fungal properties are therefore weaker than organic acids (Strom et al. 2002; Magnusson and Schnurer 2005) but could contribute to the inhibition fungal growth in silage and the risk of mycotoxin production.

In addition LAB strains isolated from plants have been shown to eliminate a variety of mycotoxins including Ochatoxin, patulin and Aflatoxins, and the fusarium toxins deoxynivalenol, zearalenone and fumonisins. Further research is needed to show the degree of degradation in the ensiling environment but intialfindings from Belgium seem to suggest that LAB could play a role in mycotoxin decontamination. They are currently only a few studies but L. plantarum has been shown to reduce Ocharatoxin levels by 80% after the fermentation of meadow sward and maize plants (Zielinska et al., 2014)

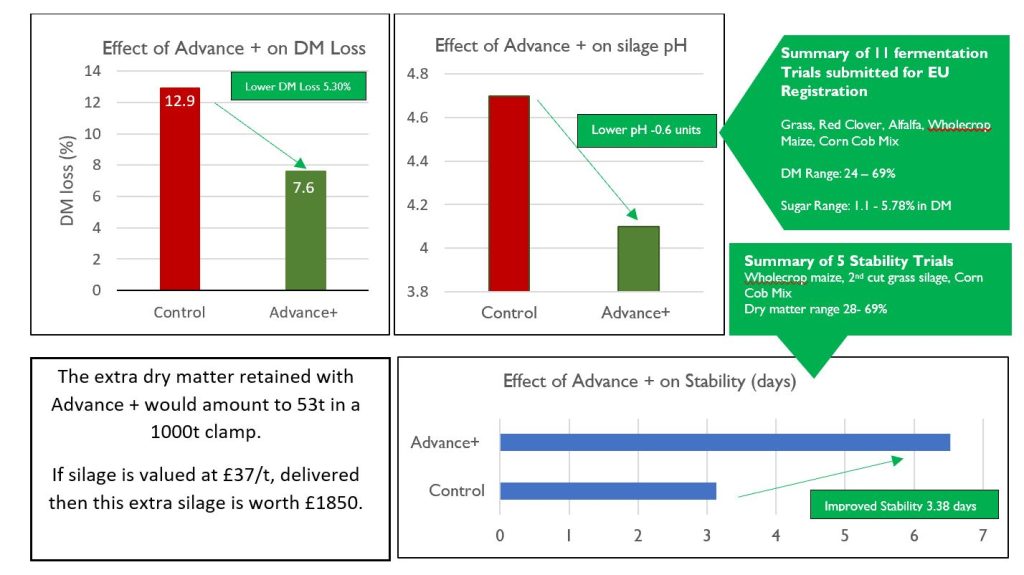

These combined activities translated into the following benefits in trials submitted to the EU for registration approval:

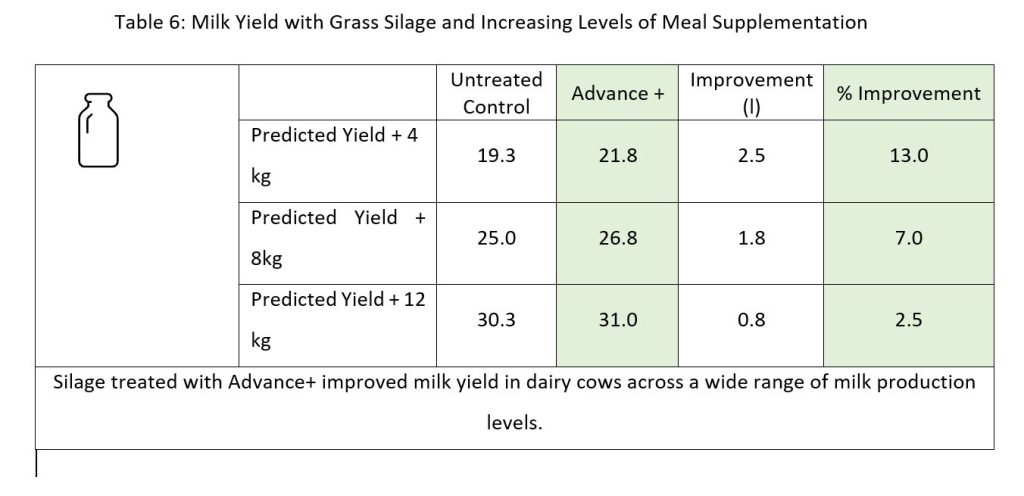

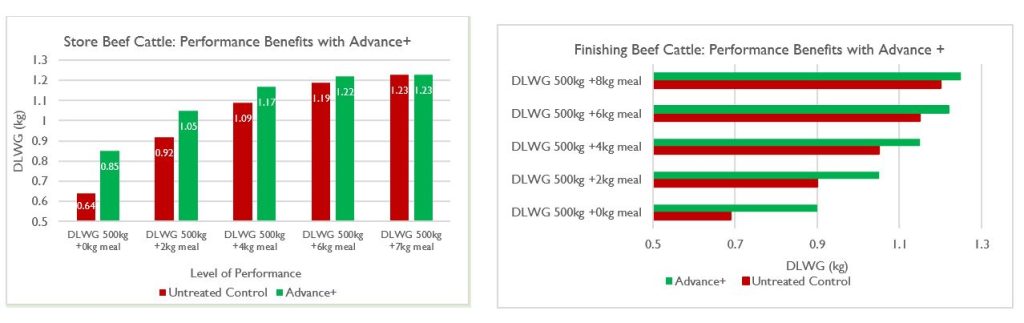

Field trials with dairy cows and beef cattle at a number of research institutes including AFBI in N. Ireland have also demonstrated the positive effects of Advance+ on animal performance. The predicted benefits using an intake model are shown below:

The predicted growth of store beef cattle fed was greater on the Advance+ treated silage across a wide range of performance levels, and this was also the case with finishing beef cattle. All indications point to the production of silage which is superior in its chemical and nutritional analysis.

Microbial Silage Inoculants: More Silage, More Nutrients

Intensive research programmes continue to refine the selection of strains of LAB, and the optimum levels of inclusion for use in microbial inoculants for silage making with various forages under differing climate conditions.

Whilst inoculants were originally designed for efficient lactic acid production, a greater understanding of the metabolism of LAB and the metabolites produced has allowed the formulation of products which have other valuable benefits.

Combinations of a number of strains of LAB also allow for:

- The production of acetic acid well recognised as a means of improving stability, and preventing the growth of filamentous fungi when clamps are opened reducing dry matter losses and heating. As well as anti-fungal activities, there is increasing evidence that LAB can reduce levels of mycotoxins in forage – maize silage has been shown to be widely contaminated with these toxic molecules that can effect gut health and reproductive performance.

- Unlocking of valuable fermentable substrate from lignified material through the production of Carboxylesterase enzymes which break the bonds between arabinoxylan and lignin in mature material such as whole crop cereals. This improves degradability of the cell wall and the potential to supply more energy in the rumen.

- Inoculant treated silage can modulate rumen fermentation to produce more propionate, and less methane so important when agricultural production systems are being asked to reduce greenhouse gas emissions.

Together these benefits can work to produce silage, which is stable, palatable and highly digestible leading to improved animal performance. Making the most of home-grown forage in this way will certainly make a difference to the bottom line of ruminant livestock enterprises – a small investment in an inoculant such as the multi-strain Advance+ will lead to superior quality silage and animal performance.